1910

The L’Air Liquide French Joint-Stock Society establishes the first oxygen factory in Warsaw at ul. Leszno 138. At the same time, in the same year the “PERUN” Joint Stock Company is established in Saint Petersburg.

1913

The L’Air Liquide French Joint-Stock Society joins the “PERUN” Joint Stock Company in the Russian state. The technical gas production plant is moved to ul. Grochowska in Warsaw, where an auxiliary welding workshop is also established.

1918

Now, the “PERUN” French Joint-Stock Company operates solely in Poland, expanding the production of equipment and taking over existing technical gas production plants in Poznań, Bydgoszcz, Lviv, Trzebinia and Dąbrówka Mała in Silesia. A new oxygen production plant was built in Skarżysko-Kamienna and an acetylene production plant was built in Bydgoszcz.

1918-1920

The production of welding equipment is developing dynamically. The “PERUN” Joint-Stock Company is the first in the country to organise the production of gas welding equipment and fittings related to the production and use of technical gases. The production was based on documentation, designs and deliveries of some parts and units from “Air Liquide” – a co-shareholder of the “PERUN” Joint-Stock Company. During the following years, the equipment developed in the country was also put into production and sale.

Perun factory staff in Warsaw in 1918

1924

“PERUN” activates the first arc welding electrode production plant. The production of “Pertrans”, “Pertrans 3F” welding transformers as well as “Peral”, “A.L.T.” and “Monobloc” rotary welding machines is started.

1929–1930

“PERUN” makes the entire first welded building structure in Poland, the PKO bank building in Warsaw. Making such a large completely welded structure for the construction industry (700 tonnes) has become an achievement on a European scale.

Perun staff in 1935.

1936

“PERUN” receives a gold medal for the whole production at the Exhibition of the Metal and Electrotechnical Industry in Warsaw.

President of the Republic of Poland prof. I. Mościcki at the Perun stand during the Exhibition of the Metal and Electrotechnical Industry – 1936.

1939-1944

During the occupation, the factory worked under the German supervision but the management was Polish. The activity of the factory, however, was severely limited and production reduced. Only technical gases and basic welding equipment were produced at the scale necessary for the operation of the factory.

1944-1945

The production was resumed under new political conditions. The company was nationalised and received a new name – Warsaw Factory of Technical Gases and Welding Equipment.

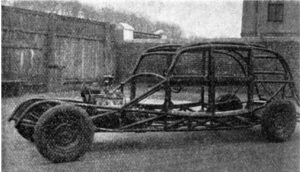

A frame car structure made of Perun

acetylene-welded pipes – 1935

1956

The construction of the new Warsaw-Targówek Technical Gas Production Plant was completed, which was then separated from the factory as an independent enterprise. The factory was transformed into the “PERUN” Warsaw Factory of Welding Equipment.

1957

The Enterprise Design Office is established. From that moment, projects of a new type of equipment and modernisation of the equipment produced so far are being developed on site.

1964-1970

“PERUN” establishes cooperation with the Welding Institute in Gliwice which results in the development of automatic cutters controlled magnetically and photoelectrically.

1970-1980

This decade is the further development of own structural and technological studies. Large cutters with CNC numerical control are created in cooperation with the Welding Institute in Gliwice.

1990’S

Along with the change of the political and economic situation in the country, it became necessary to adapt quickly to the new conditions and requirements of the market economy. Monitoring customer needs and their growing quality requirements as well as increasing competition forced to respond quickly to changes occurring in this market. Thanks to internal changes and widening of the product range, the company met these requirements and kept the position of one of the main suppliers of welding equipment in the country.

September 1999

The beginning of the privatisation process of “PERUN” Warsaw Factory of Welding Equipment.

May 2003

The privatisation process is completed – PERUN remains in Polish hands.

It starts operating on new rules as Perun Sp. z o. o.

July 2005

Perun Sp. z o. o. introduces the ISO 9001:2000 quality certificate.

February 2006

Change of the ownership form into a joint-stock company.

August 2008

Five years of activity as a private company – PERUN strengthens its position in the welding market; introduces new solutions, increases sale. The period of internal changes and adaptation to the new conditions of the company’s operation coincided with Poland’s preparations and accession to the European Union. Keeping the position of the largest Polish producer of welding and gas equipment by PERUN S.A. is even a greater success.

2017

“PERUN” is able to develop and produce any welding equipment using gas as a working medium. The quality of our production is comparable with world products in this field. Today, after more than 100 years of uninterrupted production of welding equipment, PERUN remains the leader in the production of gas equipment for welding and cutting.

The transfer of white-collar workers from the Łosice Production Department from the old office building to the new office part in the production hall 1-88.

2018

The beginning of the expansion of the sector of the sector which includes the modernization of production: 1-81 (Assembly), 1-75 and 1-39.

Purchase of the first multipurpose Goodway SW-32 longitudinal machine and BAUER VERTICUS I 180 compressor, which bypassed the test field in building 1-81.

2019

PERUN S.A. firmware and COMARCH ERP XL system – a very well-organized program of corporate organizational and digital content: production management, sales service, procurement, logistics, logistics.

Launch of a new production situation

Order / Launch of a new production hall in order to transfer the entire production to a branch in Łsosice.

Launch of a new production situation

Purchase of new machines – including a Goodway SW-32II automatic lathe with an additional Y axis for machining details in the counter-spindle.

September 2019

Change of the company’s headquarters from ul. Grochowska 301/305 and ul. Grochowska 10 in Warsaw

The company’s hard work in the field of the populus ecosystem of the photovoltaic installation, thanks to which the most ecological energy is currently obtained for mankind.

Start working in the Solid Edge software used to design a wide range of products – from the details side to the sale of assemblies with dozens of parts.

2020

The year is extremely developmental for the PERUN company – an online store for individual customers is launched and a new production hall is opened, which has been equipped with new machines for the production of gas welding devices, including multi-purpose automatic machines.

2021

The company purchased a new low pressure compressor to replace an old, worn out machine. The liquidation of old buildings, unsuitable for renovation, allows for the acquisition of land for possible expansion with a new production hall.

Moving the warehouse of semi-finished products and the entire reducer assembly department to the adjacent building, which improves the ergonomics of the workplace and production logistics.

2022

The company bought CNC lathes with a GOODWAY GLS-1500LMS interception and a bar feeder. In the company, it is a new type of machine with new possibilities. The lathe is adapted to very precise machining with high precision with repeatability of details with simple and very complex shapes. The detail is finished in one clamping, which significantly shortens the machining time.

Purchase of a KIMLA Blakbird 1520 plotter with a vacuum table. The machine opens up new solutions in terms of product packaging and gives new technological possibilities for processing paper, rubber and plastics.

2025

Change of the company’s headquarters from ul. Grochowska 10 and ul. Płowiecka 1 in Warsaw